The versatility of modern feed pellet making machines raises the question of whether machines designed specifically for goat feed can also produce forage pellets. This article examines the capabilities of goat feed pellet making machines for forage pellet production, addressing the challenges, potential solutions, and considerations for those looking to diversify their pellet production.

Understanding Goat Feed Pellet Making Machines

Goat feed pellet making machines are designed to process various ingredients into compact, digestible pellets. Key components include:

- Grinding Mechanism: Reduces raw materials to a smaller particle size.

- Mixing Unit: Ensures even distribution of ingredients.

- Conditioning Chamber: Prepares materials for pelleting by adjusting moisture and temperature.

- Pellet Mill (often with a ring die): Compresses materials into pellets.

- Cooling and Drying System: Lowers pellet temperature and moisture for storage.

Forage Pellets: A Different Challenge

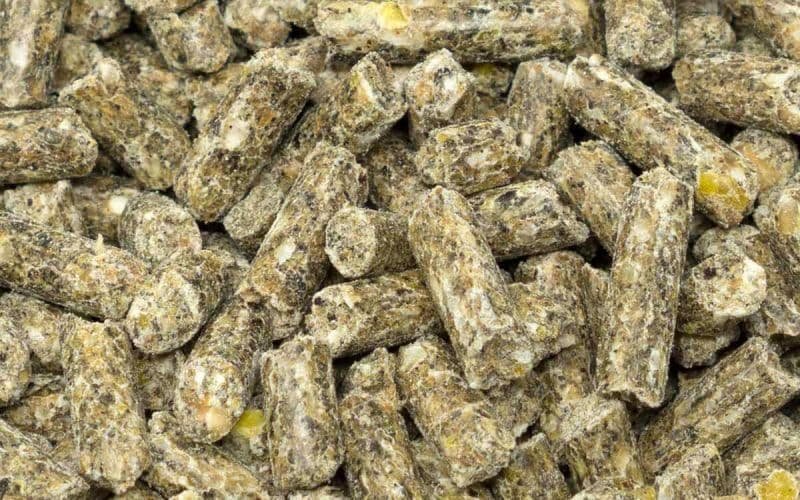

Forage pellets, made from grass, hay, or other fibrous materials, present unique challenges:

- Higher Fiber Content: Requires more energy and processing.

- Lower Natural Binding Properties: May need additional binding agents for pellet integrity.

- Variable Moisture Content: Consistency is crucial for effective pelleting.

- Potential for Longer Stem Lengths: Needs more thorough grinding.

Can Goat Feed Pellet Machines Handle Forage?

Yes, many goat feed pellet making machines can process forage into pellets, but certain considerations and modifications may be necessary:

- Pre-processing Requirements:

- Forage materials typically require more extensive grinding to achieve a smaller particle size. A dedicated forage grinder or hammer mill may be necessary.

- Moisture Content Adjustment:

- The ideal moisture content for pelleting is generally between 10-18%. A moisture meter and conditioning system are crucial for achieving consistent results.

- Die Specifications:

- The pellet die may need adjustment to accommodate the fibrous nature of forage. Larger die holes or different length-to-diameter ratios might be necessary.

- Binding Agents:

- Forage materials often lack natural binding properties. Adding small percentages of binding agents (e.g., molasses, lignosulfonate) may enhance pellet integrity.

- Production Rate:

- Processing forage may result in lower production rates compared to standard goat feed ingredients. Adjustments to feed rates and processing parameters may be required to maintain pellet quality.

Advantages of Using Goat Feed Pellet Machines for Forage

- Versatility: The ability to produce both goat feed and forage pellets increases operational flexibility.

- Space Efficiency: A single machine for multiple purposes saves valuable space in feed mills or farms.

- Cost-Effectiveness: Investing in one versatile machine is often more economical than purchasing separate machines.

- Nutritional Control: Pelletizing forage allows for precise control over nutritional content and supplement addition.

- Reduced Waste: Pelletized forage minimizes waste compared to loose hay or grass, as animals are less likely to sort or trample feed.

Considerations for Successful Forage Pelleting

To effectively process forage pellets using a goat feed pellet making machine, consider the following:

- Raw Material Preparation: Invest in proper grinding equipment for appropriate particle size and consistent moisture control.

- Machine Modifications: Consult with the machine manufacturer regarding necessary modifications for efficient forage processing. Interchangeable dies may be beneficial.

- Formulation Adjustments: Experiment with forage-to-binder ratios and blend forage with other ingredients to improve binding and nutritional profile.

- Quality Control: Implement rigorous quality control measures to ensure consistent pellet density, durability, and nutrient content.

- Operational Parameters: Adjust machine settings like die speed, roller gap, and feed rate to optimize forage pellet production.

- Cooling and Storage: Adequate cooling prevents moisture condensation and mold growth, while proper storage maintains pellet quality.

Potential Limitations

While many goat feed pellet machines can process forage, consider these limitations:

- Production Capacity: Output for forage pellets may be significantly lower than for standard goat feed.

- Wear and Tear: Processing fibrous materials may increase wear on machine components, leading to higher maintenance costs.

- Energy Consumption: More energy may be needed for forage processing compared to traditional ingredients.

- Pellet Quality: Achieving consistent quality with pure forage can be challenging and may require careful adjustments.

Conclusion

In conclusion, many goat feed pellet making machines can process forage pellets, but success relies on proper raw material preparation, potential machine modifications, and careful processing attention. The ability to produce both goat feed and forage pellets with a single machine offers significant advantages in versatility and cost-effectiveness. (Related post: livestock feed pellet machine)

However, farmers and feed manufacturers should be aware of the challenges and limitations associated with processing forage. A thorough evaluation of production needs, consultation with machine manufacturers, and investment in process optimization are crucial for success. With the right planning and execution, many operations can effectively expand their pellet production capabilities to include both goat feed and forage pellets, enhancing flexibility and creating new market opportunities.