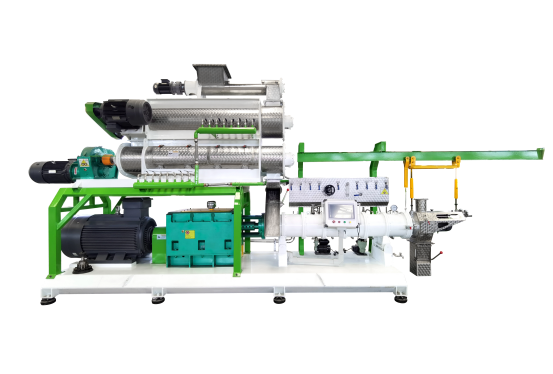

Twin-screw pet food extruder machines are known for their versatility in producing a wide range of pet food products. But can these machines also be utilized to produce high-quality fish feed? The answer is yes. Twin-screw extruders are not only capable of processing fish feed but also offer several advantages in doing so. This article delves into how twin-screw extruders can be effectively used for fish feed production, the benefits they offer, and important considerations for manufacturers.

Adapting Twin-Screw Extruders for Fish Feed Production

Twin-screw extruders, originally designed for pet food, are highly adaptable and can be effectively used to produce fish feed. Here’s why:

- Versatile Ingredient Handling: These machines can process a wide variety of ingredients commonly used in fish feed, such as fish meal, soybean meal, wheat flour, and various nutritional additives.

- Precise Control: Twin-screw extruders allow for exact control over key parameters like temperature, pressure, and shear forces, which is essential for producing different types of fish feed.

- Floating and Sinking Pellets: By adjusting the extrusion settings, these machines can produce both floating and sinking fish feed pellets, catering to the dietary habits of various fish species.

Types of Fish Feed Produced by Twin-Screw Extruders

Twin-screw pet food extruders can produce several types of fish feed, including:

- Floating Pellets: Ideal for surface-feeding fish.

- Slow-Sinking Pellets: Suitable for fish that feed in mid-water.

- Fast-Sinking Pellets: Designed for bottom-feeding species.

- Micro-Pellets: Suitable for small fish or fry.

- High-Protein Pellets: Tailored for carnivorous fish that require higher protein levels.

Advantages of Using Twin-Screw Extruders for Fish Feed

There are several key advantages to using twin-screw extruders for fish feed production:

- High-Protein Processing: These machines can handle high-protein formulations, essential for the dietary needs of many fish species.

- Improved Digestibility: The extrusion process enhances ingredient digestibility, leading to better feed conversion ratios.

- Ingredient Flexibility: Twin-screw extruders can work with a wide variety of ingredients, allowing for the creation of nutritionally balanced fish feeds.

- Consistent Quality: The precise control offered by twin-screw extruders ensures uniform quality, which is crucial for fish growth and health.

- Water Stability: Extruded fish feed has improved water stability, reducing nutrient loss and minimizing water pollution in aquaculture systems.

- Scalability: These machines come in various sizes, making them suitable for both small-scale and large commercial fish feed production.

Considerations for Producing Fish Feed

While twin-screw extruders are effective for fish feed production, certain considerations must be kept in mind:

- Formulation Adjustments: Fish feed often requires different nutrient profiles compared to pet food, necessitating changes in the formulation.

- Moisture Content: Fish feed typically requires higher moisture content than most pet foods, which may require adjustments in the extrusion process.

- Die Selection: The correct die configuration is essential for producing the specific pellet sizes and shapes needed for different fish species.

- Post-Extrusion Processing: Additional equipment, such as dryers and coolers, may be necessary to achieve the desired final product characteristics.

- Regulatory Compliance: Ensure that the extruder and the production process meet local regulations and standards for fish feed production.

Technological Advancements

Recent advancements in twin-screw extrusion technology have further enhanced their application in fish feed production:

- Improved Screw Designs: New screw configurations allow for better mixing and cooking of fish feed ingredients.

- Advanced Control Systems: Modern PLC systems offer precise control over the extrusion process, ensuring consistent product quality.

- Energy Efficiency: The latest twin-screw extruders are more energy-efficient, helping to reduce production costs.

- Integrated Systems: Some manufacturers now offer complete extrusion lines designed specifically for fish feed, integrating pre-conditioning, extrusion, and post-extrusion processing.

Market Trends and Future Prospects

The ability of twin-screw pet food extruders to process fish feed aligns well with current market trends:

- Growing Aquaculture Industry: As aquaculture expands, there is a rising demand for high-quality fish feed.

- Sustainable Feed Formulations: Twin-screw extruders can process alternative protein sources, supporting the trend toward sustainable fish feed formulations.

- Functional Feeds: These machines can incorporate functional ingredients like probiotics and immunostimulants, catering to the demand for value-added fish feeds.

- Customization: The flexibility of twin-screw extruders allows for the production of species-specific and life-stage-specific fish feeds.

Conclusion

Twin-screw pet food extruders demonstrate remarkable versatility in their ability to process fish feed effectively. Their adaptability to handle various ingredients, produce different types of pellets, and maintain consistent quality makes them valuable assets in aquaculture feed production. The advantages of using twin-screw extruders for fish feed, such as improved digestibility, water stability, and the ability to handle high-protein formulations, align well with the requirements of modern aquaculture.

For manufacturers looking to diversify their product offerings or enter the fish feed market, investing in a twin-screw extruder capable of producing both pet food and fish feed offers a strategic advantage. This flexibility allows them to meet diverse market demands and adapt to changing trends in both the pet food and aquaculture industries.

As the aquaculture industry continues to grow and evolve, the demand for efficient and versatile feed production equipment is likely to increase. Twin-screw extruders, with their proven track record in pet food production and adaptability to fish feed processing, are well-positioned to meet this demand, contributing significantly to the sustainability and productivity of aquaculture operations worldwide.