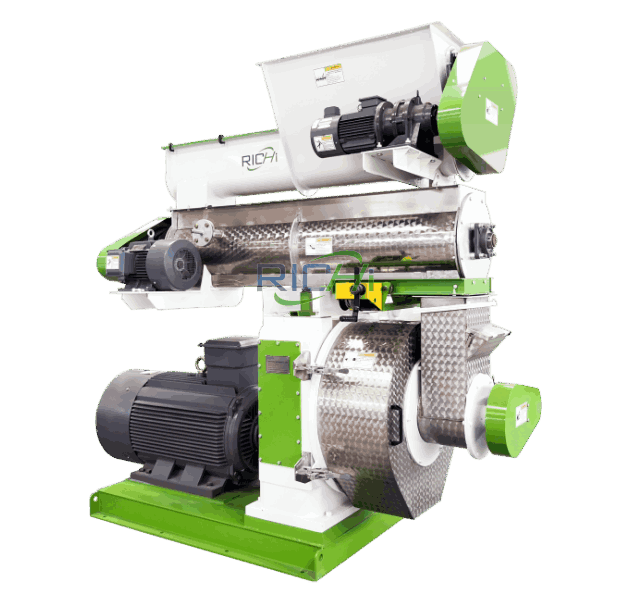

In the feed industry, it is often referred to as “conditioning”, that is, hydrothermal treatment of pellet feed powder materials. International studies have shown that conditioning is an important factor in pellet feed quality.

With the continuous improvement of the quality requirements of poultry feed pellet making machine, various poultry feed pellet machine enterprises are also paying more and more attention to the conditioning process in feed processing.

Improving conditioning equipment is currently an important aspect to improve the quality of pellet feed products and improve market competitiveness. one of the means. At present, the material conditioning machine is mainly used for the production of aquatic products and advanced animal feed.

1.It is composed of paddles or augers and nozzles.

There is often water vapor, syrup or water in the poultry feed pellet making machine conditioner. The longer the conditioning time, the better.The use of a certain temperature can kill most of the pathogenic bacteria of the material and ensure the hygiene of the feed. (Related post: cat litter making machine)

2.Improve the water resistance of pellets.

After conditioning treatment, the viscous components in the material gelatinize starch, which can give full play to the role of denatured protein as a binder, and can effectively bind other components around. The granules are more closely combined, so that the pellets are denser, have a beautiful appearance, and are not easily eroded by water, thereby improving the stability of the pelleted feed in water.

3.Improve material granulation performance and increase output.

By increasing the poultry feed pellet making machine granulation link, the energy consumption of granulation can be saved to a certain extent, and the service life of the pressing die and the pressing roller can be improved.

By quenching and tempering the pellets, the material becomes softer and more plastic, and the frictional resistance is reduced when extruding the hole wall, the inner wall of the die, and the surface of the roller body, which avoids the conversion of a large amount of mechanical energy into heat energy during the poultry feed pellet making machine pelletizing process. Slow down the wear of die and roller.

4.How arepoultry feed pellet making machine maintained?

As a poultry feed pellet making machine user, before debugging the poultry pellet feed processing equipment and production, you need to read the equipment’s operating instructions carefully.

At the same time, we should also fully understand the structure and principle of poultry feed processing machine, understand its functions and operating procedures, operate in strict accordance with the operating procedures, and conduct patrol inspections in accordance with the operating procedures and precautions.

If you operate in strict accordance with the operating procedures, you should also remember the following work:

In general, poultry feed pellet making machine manufacturers have conducted multiple inspections and verifications before the equipment leaves the poultry pellet machine factory. Meanwhile, the motor has been lead sealed and the couplings have been calibrated. Please do not loosen.

In the process of use, the staff needs to regularly sort out the iron impurities on the permanent magnet cylinder and the permanent magnet plate of the feeder. During the operation of the poultry feed pellet making machine, it is also necessary to carefully check whether the fineness of the crushed products meets the production requirements. (For more: RICHI pellet machine)

At the same time, attention should also be paid to investigating the operation status of the poultry feed pellet making machine, especially after a period of use, the dust collector bags should be regularly arranged or replaced (to ensure that the bag is ventilated), and the working status of the solenoid valve should be checked regularly (to see if it can work normally) . In addition, the wear of each wearing part should be checked regularly and replaced if necessary.

Manufacturers of poultry feed pellet making machine should also pay attention to the vibration of feed processing equipment. If it is found that the hammer is severely worn and needs to be replaced, you should pay attention to weighing to ensure that the weight difference between the two opposite hammers on the two opposite (1800 direction) hammer pin shafts is ≤ 1g and the two opposite (1800 direction) hammer pin shafts, the total weight difference between the two opposite hammers is ≤2g.

If the screen is found to be severely worn and needs to be replaced, attention should be paid to whether the flatness of the new screen and the size of the screen are reasonable, whether the equipment is in place, and the screen wool faces inward.

In addition, if the poultry feed pellet making machine suddenly has abnormal conditions such as vibration and noise, it is necessary to stop the inspection immediately. In the course of daily use, we should also do a good job of smooth care.

If it is found that the output of the poultry pellet making machine suddenly drops, in addition to the material elements, it should also be checked whether the damper is in place, whether the pipeline is leaking, whether the pulse bag is blocked, and whether the solenoid valve and fan are working properly.