Shrimp feed pellet machines are essential tools in aquaculture, designed to produce feed pellets suitable for various stages of shrimp development. The size of these pellets plays a critical role in ensuring shrimp receive the proper nutrition and maintaining efficient farm management. This article delves into the range of pellet sizes that modern shrimp feed pellet machines can produce, the significance of pellet size in shrimp farming, and the factors that influence the selection of pellet sizes.

Pellet Size Range: Catering to Shrimp Growth Stages

Modern shrimp feed pellet machines are capable of producing a broad spectrum of pellet sizes to meet the nutritional needs of different shrimp species and growth stages. Typically, these machines can process pellets in the following size ranges:

- Micro-pellets: 0.5 mm to 1.0 mm in diameter

- Small pellets: 1.0 mm to 2.0 mm in diameter

- Medium pellets: 2.0 mm to 3.0 mm in diameter

- Large pellets: 3.0 mm to 5.0 mm in diameter

Advanced machines can even produce pellets as small as 0.3 mm for post-larval shrimp and up to 6.0 mm for larger shrimp species or broodstock.

Importance of Pellet Size in Shrimp Farming

The size of shrimp feed pellets is vital for several reasons:

- Feed Efficiency: Properly sized pellets ensure that shrimp can easily consume and digest the feed, maximizing nutrient absorption and minimizing waste.

- Growth Rate: The correct pellet size directly affects the growth rate of shrimp. Pellets that are too small may not meet nutritional needs, while oversized pellets may be challenging for smaller shrimp to eat.

- Water Quality: Appropriate pellet size helps maintain water quality by reducing uneaten feed, which can lead to nutrient leaching and water contamination.

- Cost-Effectiveness: Using the correct pellet size improves feed conversion ratios, leading to more economical shrimp production.

- Shrimp Health: The right pellet size reduces the energy shrimp expend while feeding, decreasing stress and promoting overall health.

Factors Influencing Pellet Size Selection

Choosing the optimal pellet size involves considering several factors:

- Shrimp Species: Different species have varying mouth sizes and feeding habits, requiring specific pellet sizes.

- Growth Stage: As shrimp grow, their ability to consume larger pellets increases, necessitating adjustments in pellet size.

- Farming System: Intensive farming systems may require different pellet sizes than extensive systems due to variations in feeding frequency and methods.

- Environmental Conditions: Factors like water temperature and salinity can affect shrimp metabolism, influencing the optimal pellet size.

- Feed Formulation: The ingredients in the feed can impact the ideal pellet size for nutrient absorption.

Pellet Size Recommendations for Different Growth Stages

While recommendations may vary based on shrimp species and farming practices, the following guidelines generally apply to different shrimp growth stages:

- Post-Larvae (PL): 0.3 mm to 0.8 mm (Weight: < 0.5 g)

- Juvenile: 0.8 mm to 1.2 mm (Weight: 0.5 g to 3 g)

- Sub-Adult: 1.2 mm to 2.0 mm (Weight: 3 g to 15 g)

- Adult: 2.0 mm to 3.0 mm (Weight: > 15 g)

- Broodstock: 3.0 mm to 5.0 mm

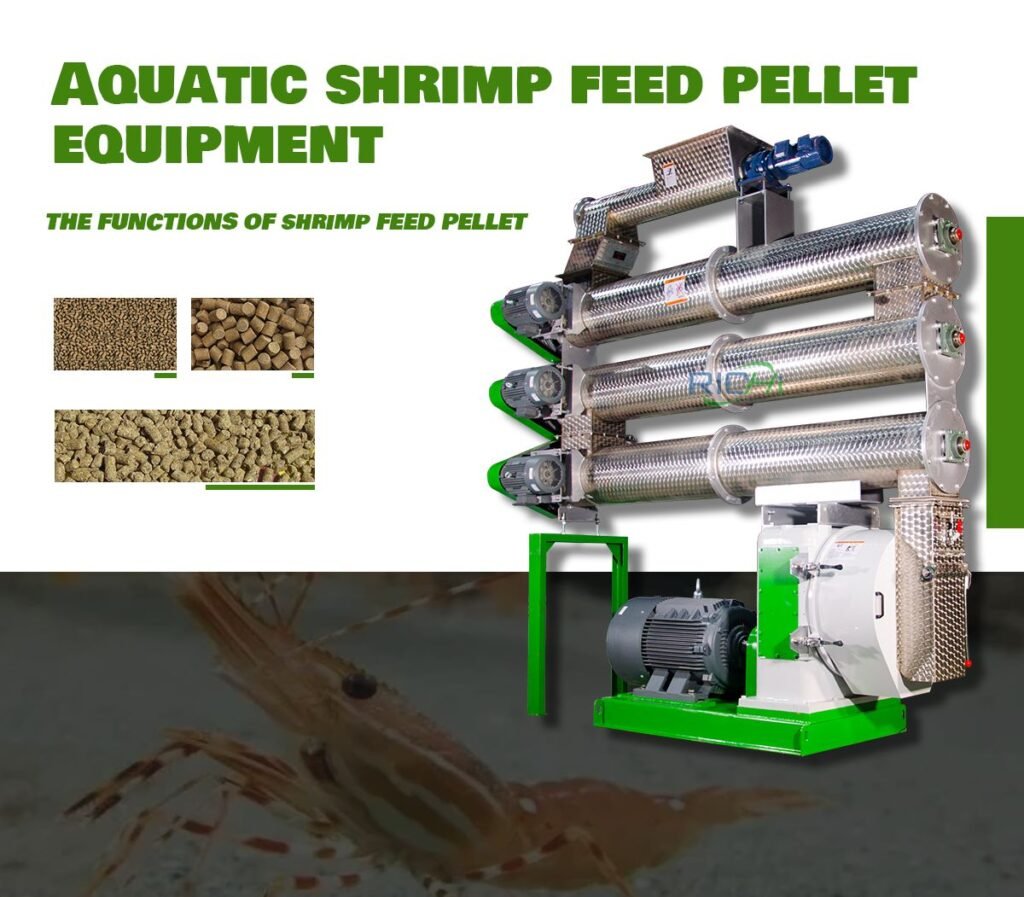

Capabilities of Shrimp Feed Pellet Machines

High-quality shrimp feed pellet machines are equipped with features that allow for the production of various pellet sizes:

- Interchangeable Dies: Modern machines come with interchangeable dies of different hole sizes, enabling quick adjustments to produce a range of pellet sizes.

- Adjustable Cutting Mechanisms: These allow for control over pellet length, offering further customization.

- Precision Control Systems: Advanced control systems enable fine-tuning of processing parameters to achieve the desired pellet size and quality.

- Multi-stage Production: Some machines can produce multiple pellet sizes simultaneously, catering to different shrimp growth stages in one production run.

- Scalability: High-end machines ensure consistent pellet size and quality across a range of production capacities.

Challenges in Producing Different Pellet Sizes

Despite their versatility, producing various pellet sizes with shrimp feed pellet machines presents some challenges:

- Die Wear: Small pellet sizes can cause faster wear of die holes, leading to more frequent maintenance or replacement.

- Throughput Variations: Smaller pellets typically result in lower throughput, affecting production efficiency.

- Formulation Adjustments: Different pellet sizes may require changes to the feed formulation to maintain nutritional profiles and pellet stability.

- Quality Control: Ensuring consistent quality across different pellet sizes requires careful monitoring and adjustment of processing parameters.

- Storage and Handling: Different pellet sizes may need separate storage and handling procedures to prevent mixing and maintain product integrity. (Related post: animal feed making machine price)

Technological Advancements

Recent innovations in shrimp feed pellet machine technology have enhanced their ability to process various pellet sizes:

- Automated Size Changeover: Advanced machines now feature automated systems for quick and precise size changes.

- Micro-extrusion Technology: New micro-extrusion techniques enable the production of smaller, more uniform pellets for early growth stages.

- Improved Die Design: Innovations in die design have led to more efficient production of a wider range of pellet sizes with improved durability and water stability.

- Integrated Sieving Systems: Built-in sieving systems ensure pellets meet size specifications by automatically removing undersized or oversized particles.

- Real-time Size Monitoring: Advanced optical systems monitor pellet size in real-time, allowing for immediate adjustments to maintain size consistency.

Conclusion

Modern shrimp feed pellet machines are designed to produce a wide range of pellet sizes, typically from 0.5 mm to 5.0 mm in diameter, with some machines capable of producing even smaller or larger pellets. This versatility is crucial for tailoring feed pellets to the specific needs of different shrimp species and growth stages.

The ability to produce precisely sized pellets is essential for optimizing shrimp nutrition, growth, and overall farm efficiency. As shrimp farming continues to evolve, with a focus on more intensive and sustainable practices, the role of well-sized feed pellets becomes increasingly significant.

Shrimp feed pellet machine manufacturers continue to innovate, offering greater precision, efficiency, and flexibility in pellet size production. For shrimp farmers and feed producers, investing in a high-quality, versatile shrimp feed pellet machine is key to meeting the diverse nutritional needs of shrimp throughout their growth cycle and maintaining a competitive edge in the rapidly growing aquaculture industry.